Selection and performance influencing factors of electrode plates and wires for electrostatic precipitators

Feb 03,2026

Polar plates and wires are the core charging and dust collection components of electrostatic precipitators. The rationality and matching of their selection directly determine the equipment's charging efficiency, dust collection effect, operational stability, and service life. This article combines practical experience from overseas industries to refine the key points for selecting electrode plates and wires, common types of adaptation scenarios, and key factors affecting equipment performance. It helps foreign trade practitioners, on-site selection and operation personnel to accurately adapt to working conditions and ensure the long-term and efficient operation of electrostatic precipitators.

1、 Plate selection (core: efficient dust collection, less prone to dust accumulation, wear-resistant)

The core function of the electrode plate is to collect charged dust. The selection should take into account the dust collection area, electrode plate stiffness, and easy cleaning of accumulated dust, and be suitable for different flue gas and dust working conditions. The common types and selection points are as follows.

(1) Common types of electrode plates and their adaptation scenarios

1. C-type electrode plate: simple structure, low cost, moderate stiffness, suitable for normal temperature, low concentration, non sticky dust working conditions (such as grain processing, small mechanical processing), moderate dust collection efficiency, easy to clean accumulated dust.

2. Z-type electrode plate: with higher stiffness than C-type, larger dust collection area, lower airflow resistance, suitable for medium high concentration and medium viscosity dust (such as conventional flue gas in building materials and metallurgical industries), and the most widely used.

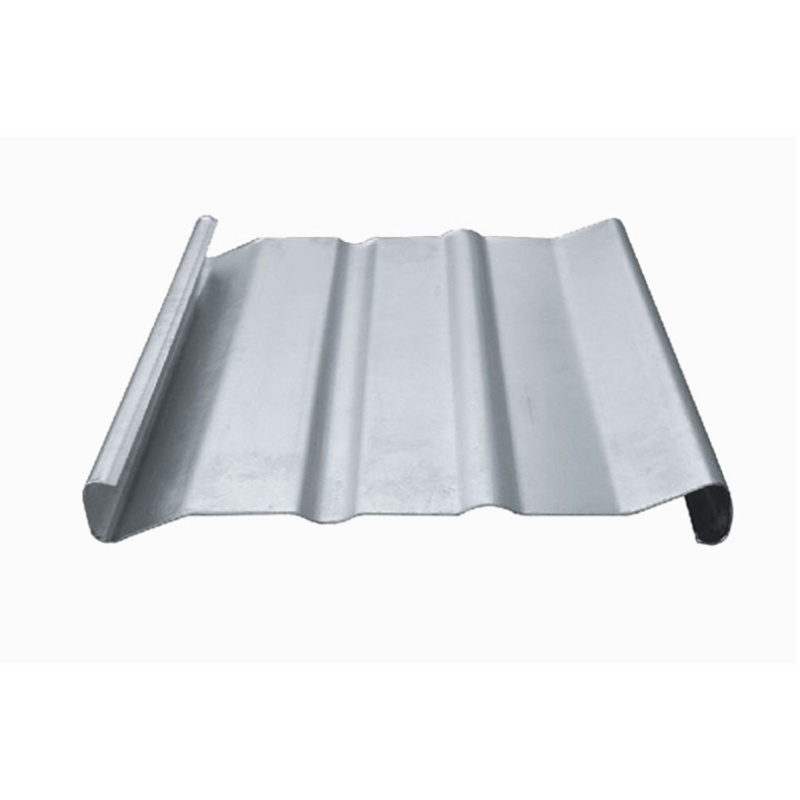

3. Wave shaped electrode plate: The surface is wavy, which can reduce airflow turbulence and avoid secondary dust flying. It is suitable for high wind speed and fine dust conditions (such as boiler flue gas in the power industry), with high dust collection efficiency, but slightly more difficult to clean.

4. Anti corrosion electrode plate (made of fiberglass, stainless steel material): Suitable for corrosive flue gas and high temperature flue gas (>300 ℃) working conditions (such as chemical and garbage incineration), corrosion-resistant and temperature resistant, with a long service life. The selection should match the flue gas corrosion level.

(2) Key points for selecting electrode plates

1. Adapt to flue gas parameters: High temperature resistant materials are preferred for high-temperature working conditions, and anti-corrosion plates are selected for corrosive flue gas to avoid plate deformation and corrosion damage.

2. Matching dust characteristics: sticky and prone to clumping dust, priority should be given to selecting electrode plates with smooth surfaces and high stiffness (such as Z-shaped) to reduce dust accumulation and adhesion; For fine dust, waveform plates are preferred to improve dust collection efficiency.

3. Balancing the vibration effect: The stiffness of the electrode plate needs to be matched with the vibration system to avoid insufficient vibration force causing dust accumulation, or excessive force causing deformation or fracture of the electrode plate.

2、 Polar wire selection (core: uniform charge, high discharge intensity, and less prone to condensation)

The core function of polar wires is to generate corona discharge, which charges dust. The selection should take into account the discharge intensity, uniformity of corona current, and avoid condensation, dust accumulation, and wire breakage. The common types and selection points are as follows.

(1) Common types of epipolar lines and their adaptation scenarios

1. Thorn wire: High discharge intensity, high charging efficiency, uniform corona current, not easy to cause corona blockage, suitable for medium to high concentration and fine dust working conditions (such as electricity, metallurgy, chemical industry), the most widely used, suitable for large electrostatic precipitators.

2. Sawtooth line: simple structure, low cost, uniform discharge, suitable for low concentration, room temperature dust working conditions (such as small mines, building materials), easy maintenance, but slightly lower discharge intensity than barbed wire.

3. Star shaped line: Smooth surface, stable discharge, not easy to condense or accumulate dust, suitable for high humidity and easily condensed flue gas conditions (such as food processing and wet dust removal matching), but with moderate charging efficiency.

4. Spiral line: It has good flexibility, is not easy to break, and is suitable for working conditions with large fluctuations in flue gas and frequent vibration (such as metallurgical furnaces), but has low discharge intensity and is not suitable for high concentration dust.

(2) Key Points for Polar Line Selection

1. Prioritize matching plate types: barbed wire and serrated wire are suitable for Z-shaped and waveform plates, star shaped wire and spiral wire are suitable for C-shaped plates, ensuring efficient coordination between charging and dust collection.

2. Adapt to flue gas humidity: For high humidity and dew prone working conditions, star shaped wires are preferred to avoid condensation and dust accumulation on polar wires, which can lead to discharge failure.

3. Considering service life: Corrosive smoke should be treated with anti-corrosion coating for polar wires (such as PTFE coated barbed wires), and high-temperature resistant materials should be selected for high-temperature working conditions to avoid polar wire corrosion and breakage.

3、 Key factors affecting the performance of polar plates and wires (refining core)

1. Matching degree of pole plate and pole line: The distance between the two needs to be precise (usually 150-300mm). If the distance is too large, the discharge intensity will be insufficient, and if it is too small, spark discharge may occur, both of which will reduce the dust collection efficiency.

2. Smoke parameters: The temperature, humidity, and corrosiveness of the smoke directly affect the service life of the electrode plate and wire material. High/low temperature can easily cause deformation, high humidity can cause condensation and dust accumulation, and corrosive smoke can easily cause damage.

3. Dust characteristics: Excessive dust concentration can easily cause corona blockage, high viscosity can lead to dust accumulation on the electrode plates and wires, and sharp particles can easily wear down the electrode plates and wires, all of which can affect equipment performance.

4. Vibration system: The vibration force and frequency need to match the pole line of the electrode plate. Insufficient force can accumulate dust, while excessive force can cause component damage and affect operational stability.

5. Installation accuracy: Excessive deviation in the installation of polar plates and wires can lead to uneven discharge, dead corners in dust collection, and reduced overall dust removal efficiency. Installation must strictly follow the specifications.

4、 Selection and operation suggestions (concise and practical)

1. Selection core: There is no optimal type, only suitable for working conditions, prioritizing the combination of flue gas and dust parameters, matching the type of electrode plate and wire, and balancing efficiency and service life.

2. Daily operation and maintenance: Regularly inspect the corrosion, deformation, and disconnection of the electrode plates and wires, promptly clean up accumulated dust, adjust vibration parameters, and avoid component damage that affects equipment performance.

3. Overseas adaptation: Based on local environmental standards and working conditions, select suitable materials and types, while also considering local operation and maintenance convenience to reduce maintenance costs.

The core of selecting electrode wires for electrostatic precipitators is "adaptation to working conditions and synergistic efficiency". The electrode plates focus on dust collection effect and durability, while the electrode wires focus on charging efficiency and stability. The matching degree and material selection of the two are the key factors determining equipment performance. When selecting, it is necessary to consider the parameters of flue gas and dust, abandon the misconception that "higher parameters are better", and prioritize adapting to actual working conditions; Pay attention to the status of components in daily operation and maintenance to ensure the long-term stable operation of electrostatic precipitators and meet the needs of overseas industrial dust control and environmental emissions.

Hot Tags:

Contact Us

Tel:

WeChat:

WhatsApp:

E-mail:

Address:

338 National Road South, Longfengdian Village, Botou City, Hebei Province, China