Industrial Dust Collectors Solution: Welding Industry

Sep 07,2024

The welding industry is indeed prone to produce smoke and dust during welding, cutting, engraving, cleaning and cladding processes. These smoke and dust not only pollute the environment, but may also harm the health of operators.

The welding industry is indeed prone to produce smoke and dust during welding, cutting, engraving, cleaning and cladding processes. These smoke and dust not only pollute the environment, but may also harm the health of operators. The following is a detailed analysis of the smoke and dust generation in these processes:

Welding process

- Source of smoke and dust: Welding smoke and dust mainly come from the gas and dust generated when the welding rod or welding wire melts at high temperature and combines with the workpiece. These smoke and dust contain a variety of harmful substances, such as metal oxides (Fe2O3, SiO2, MnO, etc.), fluorides, and harmful gases (CO, CO2, NOx, etc.).

- Characteristics: The particles of welding smoke and dust are small, fragmented, viscous, and contain high-temperature components, which makes it difficult to be completely captured by general dust removal equipment.

Cutting process

- Source of smoke and dust: Cutting smoke and dust mainly come from the gas and particulate matter generated when the cutting material (such as metal plates, pipes, etc.) is cut under the action of high-temperature heat sources (such as flames, plasma, lasers, etc.). During the cutting process, the material melts and evaporates rapidly, forming a large amount of smoke and dust.

- Characteristics: The composition and characteristics of cutting smoke are related to the cutting material and cutting process. Laser cutting produces fine smoke particles, but the smoke concentration is high; plasma cutting and flame cutting may produce more particles and smoke.

Engraving process

- Smoke source: Engraving smoke mainly comes from the debris and gas generated by engraving tools (such as laser engraving machines, mechanical engraving machines, etc.) when engraving on the surface of the workpiece. Although the amount of smoke generated during the engraving process is relatively small, it still needs to be paid attention to.

- Characteristics: The composition and characteristics of engraving smoke depend on the type of engraved material and the engraving process. Some hard materials (such as stone, metal, etc.) may produce more dust and particles during the engraving process.

Cleaning cladding process

- Smoke source: During the cleaning cladding process, when the cladding material melts at high temperature and combines with the base material, gas and dust are also generated. In addition, additional dust and particles may be generated during the cleaning process.

- Characteristics: The composition and characteristics of clean cladding smoke are related to the types of cladding materials and base materials. These smoke may contain harmful substances such as metal oxides and fluorides.

Hot Tags:

PREVIOUS:

NEXT:

Related Products

More Application

The steel industry may generate smoke and dust in multiple production links, especially in areas such as feeding, steelmaking, rolling, sintering, and blast furnace workshops. These smoke and dust not only pollute the environment, but may also harm human health.

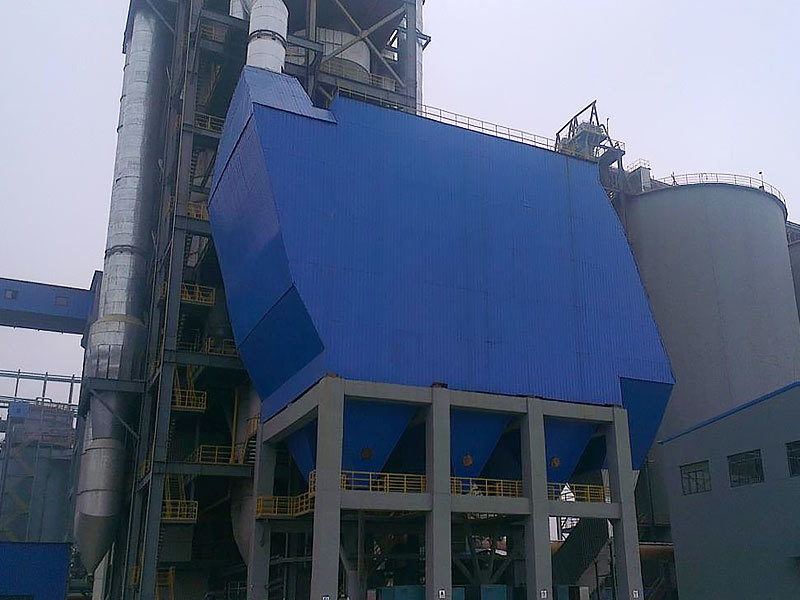

In the cement industry, smoke and dust may be generated in multiple production links, including crushers, raw material preparation, cement mills, dryers, calcination, material transportation, and packaging machines.

In the thermal power industry, coal-fired, gas-fired, biomass-fired boilers, as well as silos, coal bunkers, ash storage areas, etc. are indeed prone to generate smoke dust. These smoke dusts mainly come from the combustion process of fuels, the transportation and handling of materials, etc.

Power plants are prone to generate smoke and dust in production links such as coal transportation, pulverizing, boiler and combustion, and ash and slag systems.