Dry Wet Spray Tower

Let Our Industry Experts Create Your Tailored Solution! Contact US !

Products Category

Tag list

- Product Details

-

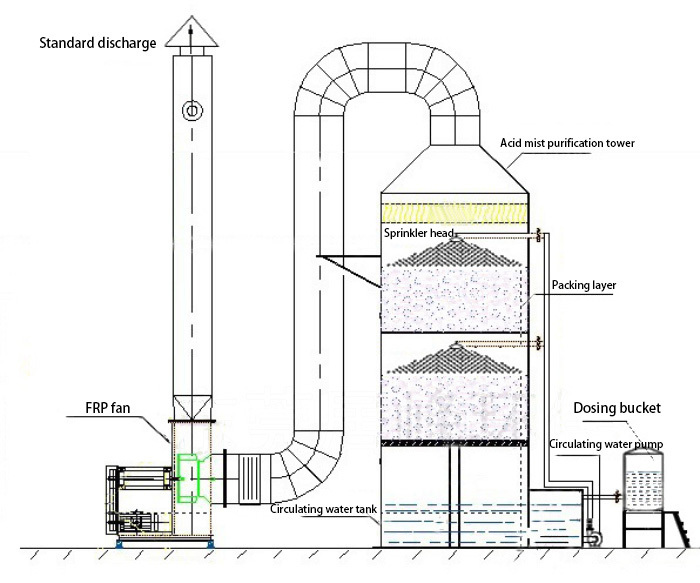

The acid and alkaline gas purification tower produced by our company belongs to gas-liquid two-phase reverse flow packed absorption tower The organic waste gas enters the purification tower from the air inlet below the waste gas treatment tower, and quickly fills the air inlet section space under the dynamic action of the fan, and then rises evenly to the first stage packing absorption section through the flow equalization section On the surface of the packing, the acidic (or alkaline) substances in the gas phase react with the alkaline (or acidic) substances in the liquid phase to form substances (mostly soluble acids (alkaline)) flowing into the lower liquid storage tank with the absorption liquid The incompletely absorbed acidic (or alkaline) gas continues to rise into the first stage spray section In the spray section, the absorption liquid is ejected from the uniformly distributed nozzle at high speed to form numerous fine droplets, which are fully mixed with the gas and continue to react chemically. Then the acidic (alkaline) gas rises to the second packing section and the spray section carries out the absorption process similar to that of the first stage The concentration range of acidic (alkaline) gas absorbed by the second stage and the first stage is different with different nozzle density and spray pressure The two-phase process in spray section and packing section is also a process of heat and mass transfer The flow rate and residence time of empty tower are controlled to ensure the sufficiency and stability of this process The uppermost part of the waste gas treatment tower body is where the absorption liquid droplets sandwiched in the gas in the demisting section are cleared down, and the treated clean air passes through the exhaust pipe atmosphere from the upper end of the waste gas purification tower

Performance characteristics

1. Waste gas treatment equipment has wide application range: organic waste gas such as sulfuric acid, nitric acid, hydrochloric acid, hydrofluoric acid and acid gases such as sulfur oxide (SOx), nitrogen oxide (NOx), carbon oxides (COCO2), cyanide (HCN) discharged from the production process of industrial departments such as chemical industry, light industry, printing and dyeing, medicine, iron and steel machinery, electronic instruments and electroplating, etc. Satisfactory results can be obtained by using positive blue environmental protection industrial waste gas purification equipment.

2. High efficiency of waste gas purification: The acid (alkali) mist waste gas purification tower adopts two-stage reverse spraying packing with large specific surface area, and the gas ratio determined by experimental study ensures stable performance. The purification efficiency of acid (or alkali) waste gas with various concentrations can reach 85% ~ 95%.

3. Low resistance of waste gas treatment equipment: On the basis of ensuring sufficient gas-liquid area, Zhenglan environmental protection industrial waste gas purification tower selects packing varieties and structural forms with aerodynamic characteristics, so that the equipment resistance does not exceed 40 mm water column under rated air volume, which is the lowest resistance among various packed absorption towers in China This is very beneficial to the use of corrosion-resistant low-pressure ventilators.

4. Waste gas treatment equipment occupies a small area: Zhenglan environmental protection industrial waste gas purification treatment tower adopts PPFRP and other materials to combine the tower body absorption liquid tank circulating pump absorption liquid pipeline system into a complete set of industrial waste gas treatment equipment with compact structure, convenient on-site installation and operation management, and small occupation area, which can be adapted to new construction projects or technical transformation projects.

Precautions

1. Before using the exhaust gas treatment equipment, check whether the pipeline valves of each system of the equipment are intact, and whether the selection and proportion of the absorption liquid chemicals are correct. When the absorption liquid fails to meet the specified requirements, it needs to be replenished in time.

2. When turning on the machine, the water pump should be turned on for 3-5 minutes before turning on the fan. When turning off this purification system, you should turn off the fan for 2-3 minutes before turning off the water pump. Do not turn it on indiscriminately, otherwise it will burn out the motor, block the packing, and affect the purification effect.

3. The wiring of the fan and water pump of the exhaust gas treatment and purification device cannot be moved casually. It must be correctly connected by professionals. It should be absolutely ensured that their steering is correct and must not be reversed, otherwise it will damage the motor and cause accidents.

4. After the exhaust gas purification and treatment equipment is put into operation and delivered, the user unit should send a dedicated person to keep it and use it. If the equipment makes abnormal sound or leaks, it should be shut down for repair before it can be used.

5. The exhaust gas purification and treatment equipment is installed outdoors, and the water pump fan motor should be made with a rainproof cover to prevent the motor from getting damp. 6. Whether exhaust gas purification treatment equipment is installed indoors or outdoors, if fiberglass or plastic fans are used, a protective cover must be installed to prevent screws from loosening, bearings from being damaged or debris from being sucked in, so as to avoid damaging the impeller and sometimes injuring people and causing accidents.

6. Replacement and matching of exhaust gas purification liquid: The formula ratio of the purification absorption liquid is determined according to the different gas sources and concentrations of the user unit. After the equipment is debugged and accepted normally, the matching ratio should be provided in detail and explained to professional management personnel.

Operating procedures

Operators must strictly follow the following instructions to carry out desulfurization and dust removal in the drying tower:

1. Pre-operation inspection:

1.1. Whether the liquid supply pump is normal;

1.2. Whether the liquid supply pipeline is unblocked;

1.3. Whether the ash discharge port of the dust collector is unblocked and whether the ash discharge ditch is unblocked;

1.4. The inspection port of the dust collector should be closed tightly;

1.5. The water volume of the circulating pool reaches the water level.

1.6. Check whether the fan is normal: the specific method is-inching the fan to observe whether the steering is correct; Jog the fan to observe whether there is any abnormal sound in the fan, and if there is any, find relevant personnel to deal with it in time; Start the fan to reach the normal speed, and observe whether the starting current is normal. If the starting current is too large, you should find relevant personnel to find out the cause and deal with it in time; After the first use and shutdown, check whether the fasteners and adapters of each component of the fan are loose. If there is any looseness, it should be dealt with in time.

2. Run the spray dust collector

2.1. Before the gas transmission from the drying tower enters the spray tower, the spray system of the spray tower must be started 5 minutes in advance to prevent the harm to the spray system caused by the excessive temperature of the gas discharged from the drying tower. It is strictly forbidden to directly put high-temperature gas into the dust collector without turning on the spray;

2.2. Check the condition of the pipeline, the supporting equipment of the system, whether the dust collector body is leaking, and the water supply system, etc.;

2.3. Check whether the fan's rotation direction, speed, bearing vibration temperature, processing air volume and pressure and temperature at each point are consistent with the design;

2.4. Repeatedly check and confirm that all safety devices are working normally;

2.5. Check the spray gun on time to see if the water pipe is blocked, and clean it up in time.

3. When stopping operation, stop the fan first and then the liquid supply pump. Check whether there is any loss in the inner parts and components of the main body of the equipment, whether the fan is normal, and repair and replace the components in time.

Dry Wet Spray Tower

Let Our Industry Experts Create Your Tailored Solution! Contact US !

Products Category

Tag list

Request a Quote

We will contact you within one working day. Please pay attention to your email.