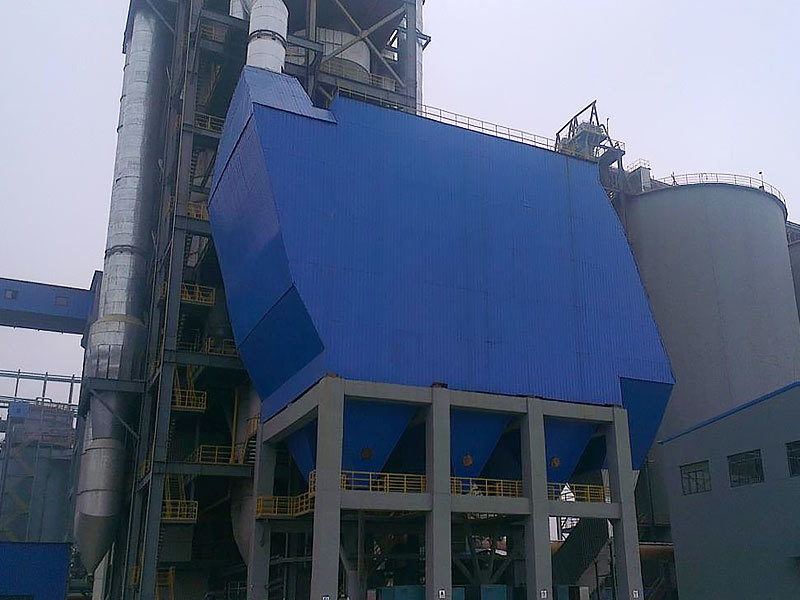

Industrial Dust Collectors Solution: Thermoelectric Industry

Sep 07,2024

In the thermal power industry, coal-fired, gas-fired, biomass-fired boilers, as well as silos, coal bunkers, ash storage areas, etc. are indeed prone to generate smoke dust. These smoke dusts mainly come from the combustion process of fuels, the transportation and handling of materials, etc. The following is a detailed analysis of the smoke dust generated in these areas:

I. Coal-fired boilers

1. Combustion process

- When coal-fired boilers burn coal, impurities in the coal (such as sulfur, silicon, etc.) will generate ash slag after combustion, most of which will become powdery substances, namely coal ash. These coal ashes are carried into the air with the flue gas to form smoke dust.

- If the combustion is incomplete, a large amount of unburned gas and particulate matter will be produced, further increasing the emission of smoke dust.

2. Material transportation and handling

- Coal will generate coal dust during transportation, crushing, screening, etc., and these coal dusts will be lifted and spread with the air.

- Since silos, coal bunkers and other areas store a large amount of coal, if they are not tightly sealed or poorly managed, they are also prone to coal dust pollution.

II. Gas boilers

1. Incomplete combustion

- The formation of smoke from gas boilers is largely due to incomplete combustion. When the fuel is not burned completely, the combustion products will remain in the flue gas, generating a large amount of smoke.

- Insufficient air is also one of the reasons for excessive smoke from gas boilers. If the boiler is not supplied with enough oxygen or the local ventilation is not smooth, the oxygen in the air will be reduced, which is not conducive to the combustion of the fuel and will produce a large amount of smoke.

2. Grate and fuel quality

- Irrational or poor grate design of gas boilers will also lead to incomplete combustion and smoke.

- The quality of fuel will also affect the formation of smoke. If the quality of the fuel is not up to standard, such as high water content, high ash content, and high impurities, it may lead to incomplete combustion of the fuel and the formation of smoke.

III. Biomass boilers

1. Combustion process

- Biomass boilers will also produce smoke when burning biomass fuels. These smoke mainly include carbon black, ash, inorganic salts, sulfur dioxide, nitrogen oxides, carbon monoxide and volatile organic matter.

- Carbon black and ash produced by incomplete combustion during biomass combustion are the main components of smoke.

2. Fuel quality and combustion technology

- The quality of fuel has an important impact on the smoke emissions of biomass boilers. If the fuel quality is poor, such as high water content and many impurities, it will lead to incomplete combustion and increase smoke emissions.

- Optimizing combustion technology and improving combustion efficiency are effective means to reduce smoke emissions from biomass boilers.

IV. Silos, coal bunkers, ash storage and other areas

1. Material storage

- Silos, coal bunkers, ash bunkers and other areas store a large amount of materials. If they are not tightly sealed or poorly managed, dust pollution is likely to occur.

- Dust may also be generated during the transportation, loading and unloading of materials.

Hot Tags:

PREVIOUS:

NEXT: