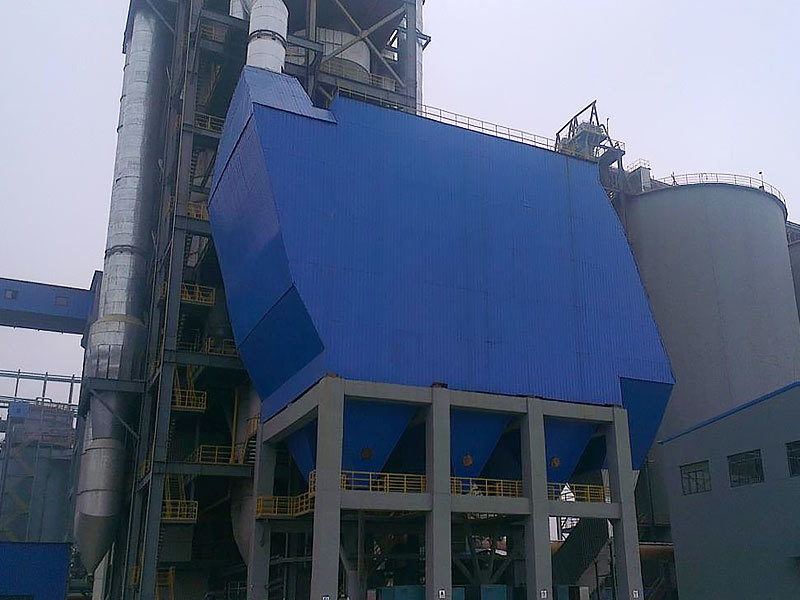

Industrial Dust Collectors Solution: Mining Industry

Sep 07,2024

The mining industry is indeed prone to smoke and dust in multiple links such as mining, ore dressing, processing, and transportation.

The mining industry is indeed prone to smoke and dust in multiple links such as mining, ore dressing, processing, and transportation. The following is a detailed analysis of the smoke and dust generated in these links:

1. Mining link

- Cause: During the mining process, the mining, blasting, and crushing of ore will generate a lot of dust and smoke. These dust and smoke mainly come from the crushing of ore, the operation of mechanical equipment, and the shock wave generated by blasting.

- Characteristics: Mining smoke often contains toxic substances, such as heavy metal dust, sulfide, etc., which are harmful to human health and the environment.

2. Ore dressing and processing link

- Cause: During the ore dressing and processing, the screening, grinding, flotation, and drying of ore will also generate smoke and dust. Especially in the grinding and flotation links, the ore is broken into smaller particles under the action of mechanical force, and reagents are added for reaction. A lot of dust and smoke will be generated in these processes.

- Characteristics: The composition of ore dressing and processing smoke is complex. In addition to the dust of the ore itself, it may also contain harmful substances such as reagent residues and organic matter. The harm of these fumes to the environment and human health cannot be ignored.

3. Transportation link

- Cause: During the transportation of ore and mineral powder, a certain amount of fumes will be generated due to the friction, collision of materials and the operation of the conveying equipment. Especially when the conveying equipment is not sealed tightly or maintained improperly, the leakage and diffusion of fumes are more serious.

- Characteristics: The particle size and concentration of conveying fumes are affected by many factors, such as conveying speed, material humidity, equipment sealing, etc. These fumes not only affect the working environment, but may also cause harm to the surrounding environment and human health.

Hot Tags:

PREVIOUS:

NEXT:

Related Products

More Application

The steel industry may generate smoke and dust in multiple production links, especially in areas such as feeding, steelmaking, rolling, sintering, and blast furnace workshops. These smoke and dust not only pollute the environment, but may also harm human health.

In the cement industry, smoke and dust may be generated in multiple production links, including crushers, raw material preparation, cement mills, dryers, calcination, material transportation, and packaging machines.

In the thermal power industry, coal-fired, gas-fired, biomass-fired boilers, as well as silos, coal bunkers, ash storage areas, etc. are indeed prone to generate smoke dust. These smoke dusts mainly come from the combustion process of fuels, the transportation and handling of materials, etc.

Power plants are prone to generate smoke and dust in production links such as coal transportation, pulverizing, boiler and combustion, and ash and slag systems.