Industrial Dust Collectors Solution: Electric power Industry

Sep 07,2024

Power plants are prone to generate smoke and dust in production links such as coal transportation, pulverizing, boiler and combustion, and ash and slag systems.

Power plants are prone to generate smoke and dust in production links such as coal transportation, pulverizing, boiler and combustion, and ash and slag systems. The following is a detailed analysis of the smoke and dust generated in these links:

1. Coal transportation system

- Coal dust generation: In the process of coal transportation, such as coal loading and unloading, and transportation, a large amount of coal dust will be generated due to the fine particles of coal and easy to fly.

- Control measures: In order to reduce the generation and spread of coal dust, power plants usually take measures such as sealing and covering, such as using closed conveyor belts and installing dust collectors, to ensure that the dust emission concentration meets the standard. According to relevant national standards, such as the "Air Pollutant Emission Standard" (GB 13223-2011) and the "Air Pollutant Emission Standard for Thermal Power Plants" (GB 13271-2014), the dust emission concentration in flue gas shall not exceed 20 mg/m3, and the dust collector efficiency shall not be less than 99.5%.

2. Pulverizing system

- Pulverizing process: During the pulverizing process, coal undergoes crushing, grinding and other processes, which will produce fine coal powder particles, which are easy to form smoke dust in the air flow.

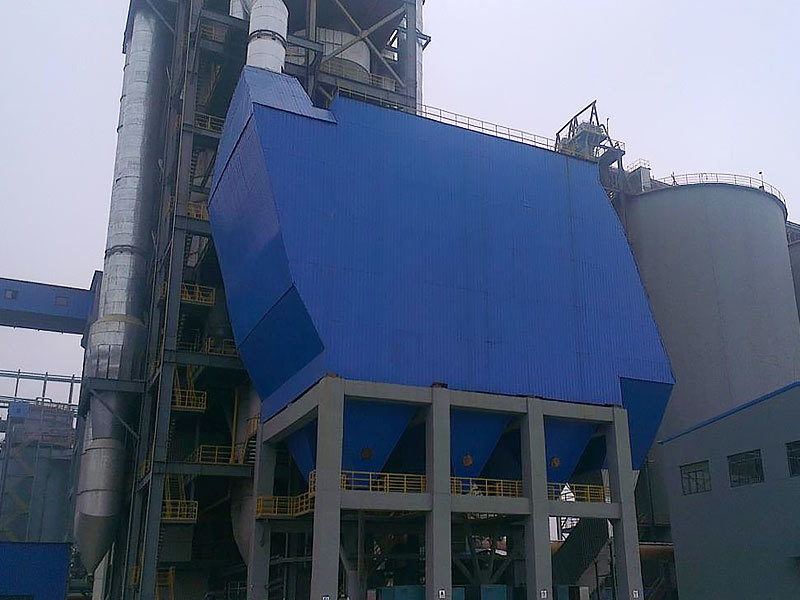

- Control measures: The pulverizing system usually also takes closed measures and is equipped with dust removal equipment, such as bag dust collectors or electrostatic dust collectors, to capture and remove the generated coal powder particles.

3. Boiler and combustion system

- Combustion process: When coal is burned in the boiler, a large amount of flue gas is generated, which contains pollutants such as smoke dust, sulfur dioxide, and nitrogen oxides.

- Control measures: In order to reduce the emission of smoke dust in the flue gas, power plants will use efficient dust removal equipment, such as electrostatic precipitators, bag dust collectors or wet dust collectors. In addition, the concentration of pollutants such as sulfur dioxide and nitrogen oxides in the flue gas will be further reduced through technical means such as desulfurization and denitrification.

4. Ash system

- Ash generation: Ash slag after boiler combustion is also easy to generate smoke dust during the processing and transportation process. Especially when ash is transported in a dry ash removal system, the flying and dispersion of ash particles will cause certain smoke pollution.

- Control measures: The ash system usually adopts a closed or semi-closed transportation method to reduce the flying and dispersion of ash particles. At the same time, the ash will be properly handled, such as comprehensive utilization or safe landfill, to reduce pollution to the environment.

Hot Tags:

PREVIOUS:

NEXT:

Related Products

More Application

The steel industry may generate smoke and dust in multiple production links, especially in areas such as feeding, steelmaking, rolling, sintering, and blast furnace workshops. These smoke and dust not only pollute the environment, but may also harm human health.

In the cement industry, smoke and dust may be generated in multiple production links, including crushers, raw material preparation, cement mills, dryers, calcination, material transportation, and packaging machines.

In the thermal power industry, coal-fired, gas-fired, biomass-fired boilers, as well as silos, coal bunkers, ash storage areas, etc. are indeed prone to generate smoke dust. These smoke dusts mainly come from the combustion process of fuels, the transportation and handling of materials, etc.

Power plants are prone to generate smoke and dust in production links such as coal transportation, pulverizing, boiler and combustion, and ash and slag systems.