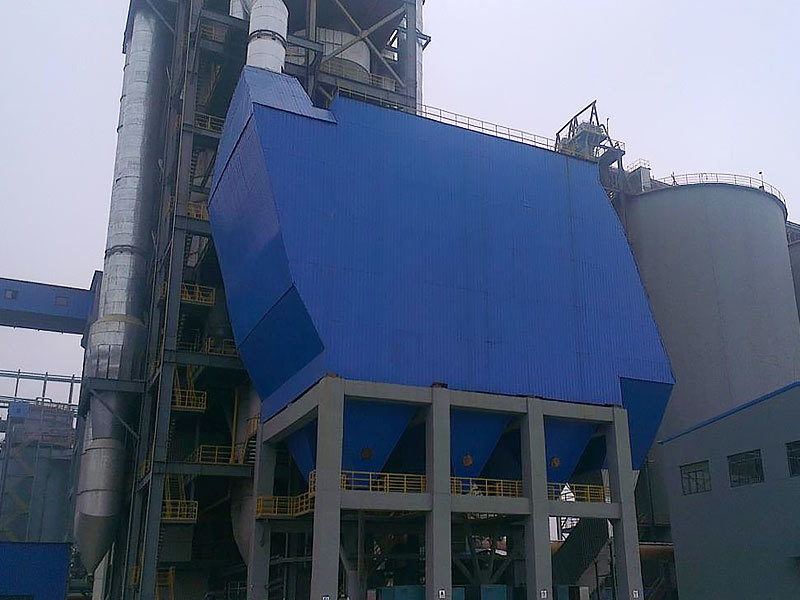

Industrial Dust Collectors Solution: Steel Industry

Sep 07,2024

The steel industry may generate smoke and dust in multiple production links, especially in areas such as feeding, steelmaking, rolling, sintering, and blast furnace workshops. These smoke and dust not only pollute the environment, but may also harm human health.

The steel industry may generate smoke and dust in multiple production links, especially in areas such as feeding, steelmaking, rolling, sintering, and blast furnace workshops. These smoke and dust not only pollute the environment, but may also harm human health. The following is a detailed analysis of the smoke and dust generated in these links:

1. Feeding workshop

- Cause: During the feeding process, the handling, crushing, and screening of raw materials such as iron ore and coke will generate a lot of dust.

- Features: The dust particles vary in size, but most of them belong to the category of industrial dust, containing harmful substances such as iron powder and coke powder.

2. Steelmaking workshop

- Cause: During the steelmaking process, raw materials such as ore, coke and solvent react at high temperatures to generate a lot of smoke and exhaust gas. Especially in the steelmaking converter blowing stage, the smoke concentration is extremely high.

- Features: The smoke contains a large amount of harmful components such as metal oxides, sulfur dioxide, nitrogen oxides, etc., with high concentration and large emissions.

3. Steel rolling workshop

- Cause: During the rolling process of steel, smoke and dust will be generated due to roller friction and oxidation of steel surface.

- Features: Although the amount of smoke and dust generated in the steel rolling workshop is relatively less than that in the steelmaking workshop, long-term accumulation still has a certain impact on the environment.

4. Sintering workshop

- Cause: During the sintering process, raw materials such as iron ore are sintered at high temperature, generating a large amount of dusty exhaust gas.

- Features: Sintering exhaust gas contains a large amount of pollutants such as particulate matter and sulfur dioxide, and the exhaust gas temperature is high and the dust content is large.

5. Blast furnace workshop

- Cause: During the blast furnace ironmaking process, the combustion of coke and the reduction reaction of iron ore will generate a large amount of blast furnace gas and smoke.

- Features: Blast furnace gas contains a large amount of pollutants such as carbon monoxide, carbon dioxide, nitrogen oxides and dust, and the smoke emission is large and the concentration is high.

Hot Tags:

PREVIOUS:

NEXT:

Related Products

More Application

The steel industry may generate smoke and dust in multiple production links, especially in areas such as feeding, steelmaking, rolling, sintering, and blast furnace workshops. These smoke and dust not only pollute the environment, but may also harm human health.

In the cement industry, smoke and dust may be generated in multiple production links, including crushers, raw material preparation, cement mills, dryers, calcination, material transportation, and packaging machines.

In the thermal power industry, coal-fired, gas-fired, biomass-fired boilers, as well as silos, coal bunkers, ash storage areas, etc. are indeed prone to generate smoke dust. These smoke dusts mainly come from the combustion process of fuels, the transportation and handling of materials, etc.

Power plants are prone to generate smoke and dust in production links such as coal transportation, pulverizing, boiler and combustion, and ash and slag systems.