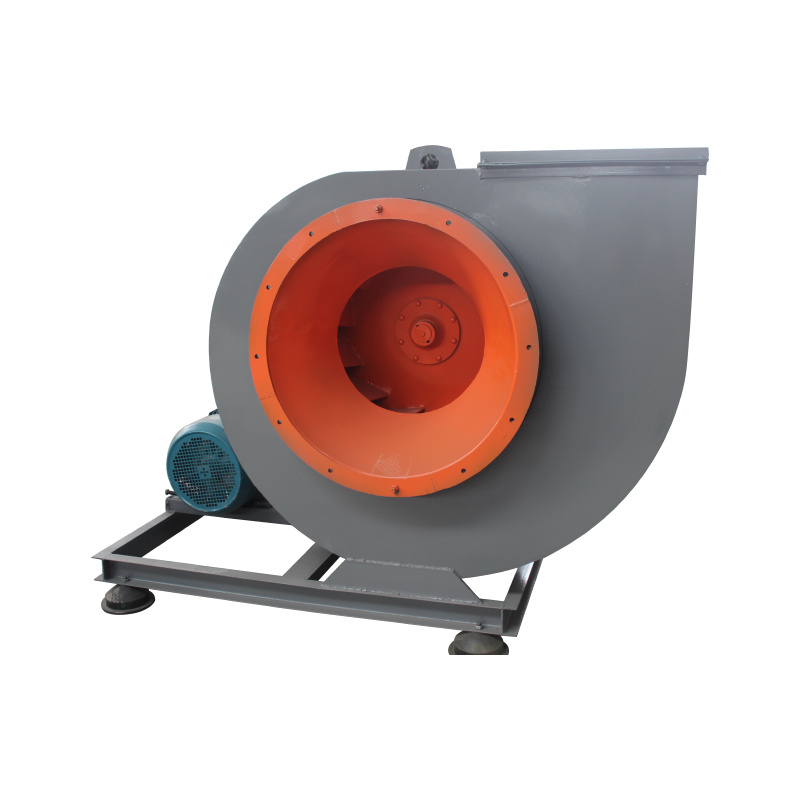

The key component of dust collector - centrifugal fan: the power source driving efficient dust removal

Jun 21,2025

In the efficient operation of dust collectors, centrifugal fans can be regarded as the "power heart", and their performance directly affects the dust removal efficiency and equipment stability. For global industrial production enterprises, a deep understanding of this key component can help optimize dust removal systems and enhance environmental efficiency.

Core working principle: The mystery of airflow drive

Centrifugal fans are mainly composed of components such as impellers, casings, air inlets, and motors. When the motor drives the impeller to rotate at high speed, the gas inside the impeller is thrown out by centrifugal force, forming a high-pressure airflow inside the casing and being discharged through the air outlet; At the same time, negative pressure is formed in the central area of the impeller, and the external dusty gas is continuously sucked in from the air inlet under atmospheric pressure, thereby achieving continuous gas delivery and providing stable suction force for the dust collector, ensuring that the dusty gas passes through the dust removal device smoothly for purification.

Three core advantages: efficient and stable guarantee

1. Strong power output: By optimizing the impeller structure and blade angle design, the centrifugal fan can provide stable and strong air pressure and volume, ensuring that the dust collector can quickly extract dusty gases under different working conditions and improve overall dust removal efficiency.

2. Stable and reliable operation: The casing and impeller are made of high-strength and corrosion-resistant materials, matched with high-precision bearings and motors, which can adapt to harsh industrial environments such as high temperature and high dust, reduce equipment failures, and ensure long-term stable operation.

3. Flexible performance adjustment: Some centrifugal fans are equipped with variable frequency control systems, which can flexibly adjust the speed according to actual working conditions, accurately control the air volume and pressure, reduce energy consumption, and achieve energy-saving operation.

Key points of scientific selection: key to adapting to working conditions

When selecting, it is necessary to comprehensively consider factors such as the type of dust collector, processing air volume, pipeline length and layout, and dust characteristics. For example, large dust collectors that handle high concentration dust require the use of centrifugal fans with high air volume and pressure; For small-scale workshop dust collectors, fans with moderate power and low noise can be selected, while ensuring that the fan material can withstand the chemical properties of dust and prevent corrosion damage.

Maintenance Guide: Extend Service Life

Regular maintenance of centrifugal fans can significantly extend their service life. It is necessary to check whether the impeller is dusty or worn, clean it in a timely manner, and calibrate the dynamic balance; Lubricate bearings to prevent damage caused by friction overheating; Monitor motor current and voltage to ensure stable operation; In addition, attention should be paid to the operating noise of the fan. Abnormal noise may indicate component failure and requires timely troubleshooting and maintenance.

As a key power component of dust collectors, the performance and selection of centrifugal fans directly affect the success or failure of the dust removal system. Choosing a suitable centrifugal fan not only ensures efficient operation of the dust collector and helps enterprises achieve environmental standards, but also reduces long-term operating costs. Whether it is heavy industry production or small and medium-sized processing enterprises, high-quality centrifugal fans are an essential choice for creating efficient dust removal systems.

Hot Tags:

PREVIOUS:

Contact Us

Tel:

WeChat:

WhatsApp:

E-mail:

Address:

338 National Road South, Longfengdian Village, Botou City, Hebei Province, China